Three-phase asynchronous motor is composed of two basic parts: fixed stator and rotating rotor. The rotor is installed in the stator cavity and supported on two end covers with the help of bearings. In order to ensure that the rotor can rotate freely in the stator, there must be a gap between the stator and the rotor, called air gap. The air gap of the motor is a very important parameter. Its size and symmetry have a great impact on the performance of the motor. Figure 2 shows the components of three-phase cage asynchronous motor. [1]

Figure 2

Figure 2 [8]

stator

The stator is composed of three-phase stator winding, stator core and frame.

Figure 3

Figure 3

Stator three-phase winding is the circuit part of asynchronous motor, which plays a very important role in the operation of asynchronous motor, and is the key component to convert electrical energy into mechanical energy. The structure of the three-phase winding of the stator is symmetrical. Generally, there are six outgoing terminals U1, U2, V1, V2, W1 and W2, which are placed in the junction box outside the base and connected into a star (Y) or triangle (△) as required, as shown in Figure 3.

The stator core is a part of the magnetic circuit of asynchronous motor. Since the main magnetic field rotates relative to the stator at synchronous speed, in order to reduce the loss caused in the core, the core is made of 0.5mm thick high magnetic conductivity silicon steel sheet, and both sides of the silicon steel sheet are coated with insulating paint to reduce the eddy current loss of the core.

The frame is also known as the casing. Its main function is to support the stator core and also bear the reaction force generated by the load operation of the whole motor. The heat generated by the internal loss during operation is also distributed through the frame. The base of medium and small motors is generally made of cast iron. Due to the large body of large motor, it is inconvenient to cast, so steel plate welding is often used for forming. [1]

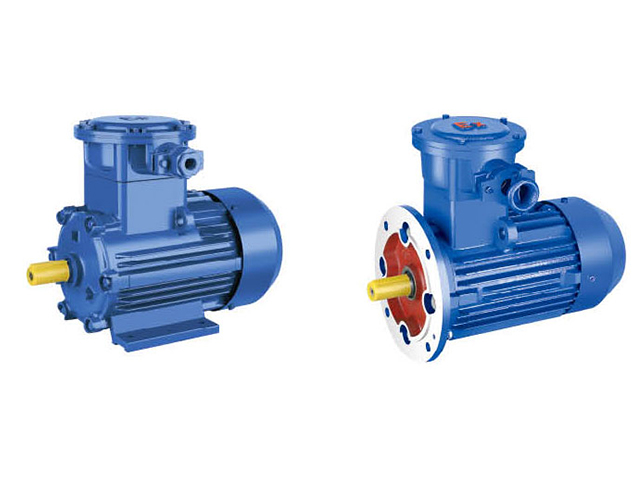

rotor

The rotor of asynchronous motor is composed of rotor core, rotor winding and shaft.

The rotor core is also part of the magnetic circuit of the motor and is also made of silicon steel sheets. Unlike the stator core punch, the rotor core punch is slotted on the outer circle of the punch, and many slots of the same shape are uniformly formed on the cylindrical surface of the stacked rotor core to place the rotor winding.

The rotor winding is another part of the asynchronous motor circuit. Its function is to cut the stator magnetic field, generate the induced electromotive force and current, and bear the force under the magnetic field to make the rotor rotate. Its structure can be divided into cage winding and winding winding. The main characteristics of these two rotors are: cage rotor has simple structure, convenient manufacturing, and is economical and durable; The winding rotor has complex structure and high price, but the rotor circuit can introduce external resistance to improve the starting and speed regulation performance.

The cage rotor winding is composed of a guide bar placed in the rotor slot and end rings at both ends. In order to save steel and improve productivity, the guide bars and end rings of small power asynchronous motors are generally cast by molten aluminum at one time; For high-power motors, because the quality of cast aluminum is not easy to guarantee, the copper bar is usually inserted into the rotor core slot, and then the end rings are welded on both ends. The cage rotor winding is closed by itself and does not need to be powered by external power supply. Its shape is like a cage, so it is called cage rotor, as shown in Figure 4. [1]

Figure 4

Figure 4

air gap

Structure diagram of three-phase asynchronous motor

Three-phase asynchronous motor structure diagram [6]

The air gap of asynchronous motor is very small. Generally, the air gap of small and medium-sized motor is 0.2~2mm. The larger the air gap, the larger the magnetic resistance. To generate the same size of magnetic field, a larger excitation current is required. Due to the existence of air gap, the magnetic circuit reluctance of asynchronous motor is much larger than that of transformer, so the excitation current of asynchronous motor is also much larger than that of transformer. The excitation current of the transformer is about 3% of the rated current, and the excitation current of the asynchronous motor is about 30% of the rated current. The excitation current is reactive current, so the larger the excitation current is.

Source: excerpts from Baidu Encyclopedia